This article was updated Nov. 8 at 7:00 p.m.

The New School’s Making Center is dealing with a series of consequences due to understaffing, according to the center’s staff. According to the staff, insufficient staffing leads to dangerous shop environments disrupts class curriculum, limits students’ access to promised resources, and blocks their creativity.

Wood and metal technician Eva Warne described the staffing shortage as potentially affecting students’ ability to safely use the shops. And there are, “Fewer technicians to keep people safe during open hours,” she said.

Warne said, “Technicians are faced with large quantities of students — almost an unmanageable amount — to keep watch over during open work time.”

The shortage of staff results in reduced professional supervision and less time to work with students on how to properly operate shop materials. In particular, Warne stated that the E4 Metal Shop and E4 Wood Shop are most impacted.

Product design professor Erika Doering, who has been teaching product design for 21 years, said, “It is just a matter of time before there’s a horrible accident. The table saw can kill you, right? You can lose fingers and other things. In the Metal Shop, it’s an explosion. That’s the risk because the gas tank is not child’s play.”

The challenge of maintaining a full staff of 50 employees is further complicated by the employee turnover timeline. The Director of the Making Center, Mick Hondlik, said, “With a staff of 50 people, there’s always going to be some vacancy statistically.”

Hondlik elaborated, “One of the issues is the process of replacing staff. From the time [a former staffer] leaves until the next person is in place and not even trained, but just physically here, can take two to three months.” Hondlik stated that the time-consuming process of rehiring makes matters worse with pre-existing staffing shortages.

The issue of underpaid staff and technicians adds an additional layer of issues: “TNS does not have a good retention rate due to the pay per hour that technicians get vs. the amount of work/teaching we do. This leads to burnout,” Warne said.

The consequences are further amplified by drastically reduced operating hours in studios and labs this semester.

Previously, these shops were closed on weekends, but starting the weekend of Nov. 2nd, the E4 Wood and Metal Shops and the N2 Wood Shop have begun offering extended weekend hours, according to a communication sent out by the Parsons Dean’s Office last week. The most up-to-date schedule is also available on the Making Center website.

Previous shop hours last semester would vary but typically ranged from 9:00 a.m. to 8:00 p.m. on weekdays and 10:00 a.m. to 6:00 p.m. on weekends. Warne stated that this is due to the lack of technicians.

“Last semester, the shop hours were entirely different. Pretty much any day, you could guarantee at least three to four hours of shop time, even on weekends … Now you’re lucky to get like two hours consecutively in E4 specifically,” third-year product design student Sophia Marson said.

As a result, the understaffing is forcing teachers to change their class curriculums from what was proposed in the original syllabus. “Professors are faced with changing projects due to the unlikelihood of all 15 of their students getting enough shop work time,” Warne said.

Projects that have historically been part of course curriculums in Parsons classes are no longer available to the next generation of students.

This was the case in one of Doering’s colleague’s chair-making courses. “Homework immediately had to change … I don’t know how they’re going to build chairs. They want to hang on to the traditional wood chairs or wood frame that they’ve been doing, [but] they’re going to have to move into totally different materials because they just don’t have the shop time,” Doering said.

“[Students are] going to have to simplify the projects because it takes hours to produce these beautiful pieces and practice making,” they added.

These staffing issues have resulted in lost access to crucial resources for students. “When final projects are due, kids who can afford to outsource and send their projects out to be produced correctly, in ways that they can’t do at the school, will have better projects,” third-year BFA product design student Julia Bosma said. “It will become a division on who is wealthy enough to afford to professionally produce their products and who can’t.”

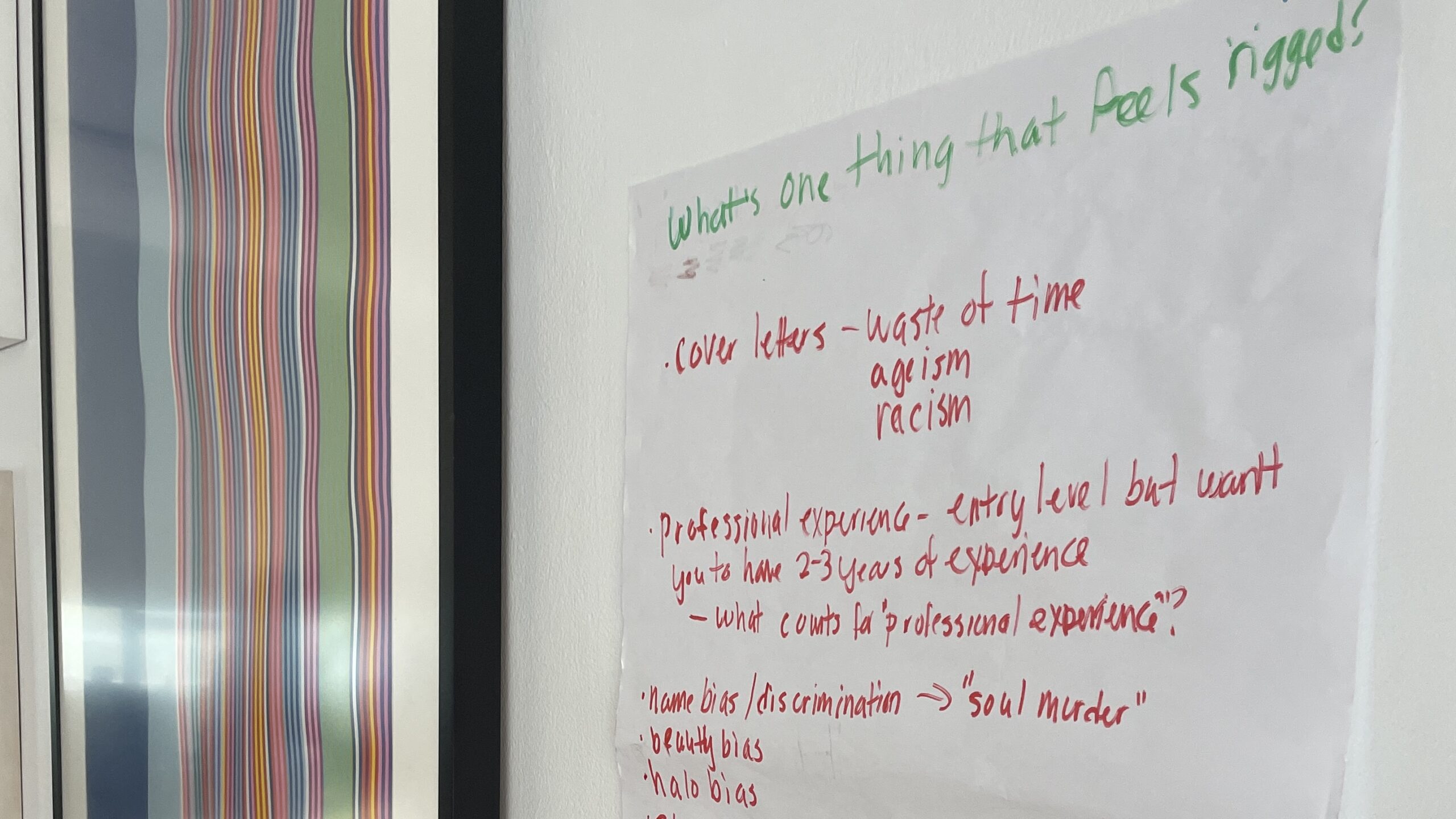

In response, students have created petitions to advocate for increased staffing and funding for the Making Center. One petition in particular calls to restore E4 and Making Center access. Another petition urges The New School to provide increased funding for the Design Lab. These efforts aim to ensure that students have access to this vital creative hub.

“The entire culture of the program and all parts of the program are very heavily centered around the Making Center … It’s where our resources are. It’s where we have community. It’s where we make friends. It’s where we share our ideas,” Bosma said.

This is an updated version of this article. The previous version stated that no weekend hours were available in the E4 Wood and Metal shops. A communication sent out to Parsons students by the Parsons Dean’s Office on Nov. 1st stated that the shops will now be open for limited hours on weekends.

This is an updated version of this article. The previous version stated the wrong Making Center hours from the Spring 2024 semester. The hours have been changed to the correct hours.

Leave a Reply